|

Consideration Issue - Packing

Protect glass in a safe condition in delivery is first target of packing. However, it is not a problem. The major problem is how to keep the glass clean. A clean surface is to be seen as a nature of glass. But the glass surface will interact with the environment. Most of the processor did wash the glass after processing. But the packing and delivery will always dirty the glass. Select a proper packing method is important.

Surface contact type:

Tape: Using an adhesive tape to cover glass surface can protect glass form scratch and allow the glass to stack each other. This way is very good in packing size and protection. The glass is stationary in the tape and will not hit each other. It can provide a safely protection during delivery. But the problem is on the adhesive glue. The glue provide adhesive which is the key of stationary. However, after removing the tape, the glue will left residual on contact surface of the glass. How clean it will be? It depends on how customer inspect it and eyesight strength of the inspector. For most inspector, the residual will not be seen under ordinary environment illumination and under 17W fluorescent light. But the residuals will be clear under the illumination of projective light souce. Under the inspection of microscope, the result is vary. Some can't see the residual, but some can. It depends on the light position, injection angle, light strength and the magnification power rate of microscope

Gel-Pak: It is used for some special small glass and hope keep the filter partly clean ( the other side contact glue) and safe. The Gel-Pak is a box filled with a layer of glue on box contact surface. the glass will be attached on the bottom firmly during the delivery. The filter can easily pick up by clip. The Gel-Pak is very expensive and only used for small size filter. Since the glass will contact the glue on one side. It has glue residual problem in filter contact surface

Tray(lying): The lying tray is a relative good but expensive container usd in glass. The glass lying on the separating cell can get a good protection from shipping virbation. There will be no scratch problem if the cell size match the glass. However, if the size of cell is not fit the glasss, the glass will impac the wall of cell and make serious damage or scratch. The particle may also be generated form some clastic small glass of the edge side. Most important of all, this tray is produced by mold injection. It is not easy to purchase existing shape and size of cell of tray that specific meet your products. The lot quantity usually is need to produce certain size tray.

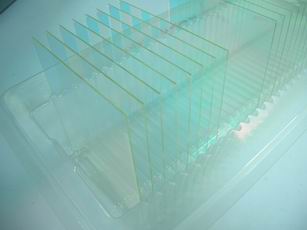

Modified Tray (stand+glue): In recent years, a modified tray type was introduced into market. In old type of tray, glass may hit the wall and produce particles which attached on glass surface. The modified tray add a small amount glue on the tray bottom and adhere the edge side of glass. This glue keep glass stantionary and prevent hit the wall. It really may reduce most particle which generated by impact. However, only a small size of glass can use this method. such as the size under 20x20mm

Add: Room 802,HongTao building, South BaoAn Road, LuoHu District, ShenZhen Guangdong China, P.R.C.

E-Mail: compass88@compass88.com

Tel: 86-755-25565171 82116272 25582430

Fax: 86-755-25892870¡¡ msn :yydilan82@hotmail.com

http://www.globalsources.com/manufacturers/Thin-Film-Filter.html |